Depureco UK - Italian Industrial Cleaning Equipment

Italian Manufacturing Since 1972

10+ Year Gurantee

Free UK Site Assessment

Alcester Showroom

Tel: 01952 588 881

THREE PHASE INDUSTRIAL VACUUM - FOX 5.5 P

Presenting the FOX 5.5 P, a robust and efficient industrial vacuum designed for reliability and power. Equipped with a 3 kW side channel turbine, this vacuum ensures continuous operation without the need for frequent maintenance.

The filter chamber features a generous surface area polyester filter (24,000 cm2), certified as M Class with a 1-micron filtration efficiency, making it adept at capturing even the finest dust particles. Safeguarding the filter is a sturdy metal cyclone welded inside the chamber, enhancing durability and performance.

For enhanced versatility, the FOX industrial vacuum offers a range of filter options to suit various professional applications. These include Teflon water-repellent filters, Nomex filters resistant to temperatures up to 250°C, and filters treated with PTFE for tackling binding and difficult dust. Additionally, upon request, the unit can be fitted with an H14 absolute filter to meet specific filtration needs.

Featuring a spacious 100-liter detachable container on wheels, operators can effortlessly collect and empty vacuumed materials. Disposable collection bags are also compatible for added convenience. Furthermore, a floating system can be incorporated into the container, ensuring safe vacuuming of liquids without compromising safety.

With its powerful performance, adaptable filtration options, and user-friendly design, the FOX 5.5 P industrial vacuum is a dependable solution for a wide range of industrial cleaning tasks.

Key Features

Suction Unit

Filtering Unit

The suction unit is a side channel blower with direct coupling between motor and impeller. The side channel blower is equipped with a safety valve to guarantee continued work in complete safety, without any maintenance. The blower is also equipped with a metal silencer to maintain a low noise level.

The filtration is guaranteed by an M class polyester filter. The star shape enables air to flow through the filter even when it is dirty. The fabric of the filter is classified as M Class (BIA | EN 60335-2-69). This means that all particles till 1 micron are stopped by the filter so as to protect the blower and the operator around the vacuum cleaner

Inlet

Collection Bin

The tangential inlet is designed to ease the process of pushing the material down the bin. A sturdy metal cyclone welded inside the chamber slows the material's entry speed considerably down so that it falls directly inside the bin. This way, the filter is efficiently protected, minimizing clogging risk.

The material is collected inside a painted container equipped with a metal handle which enables the bin to be detached from the machine. Thanks to its 4 swiveling wheels, the bin can be easily moved and emptied. Each wheel is reinforced to guarantee maximum stability during handling.

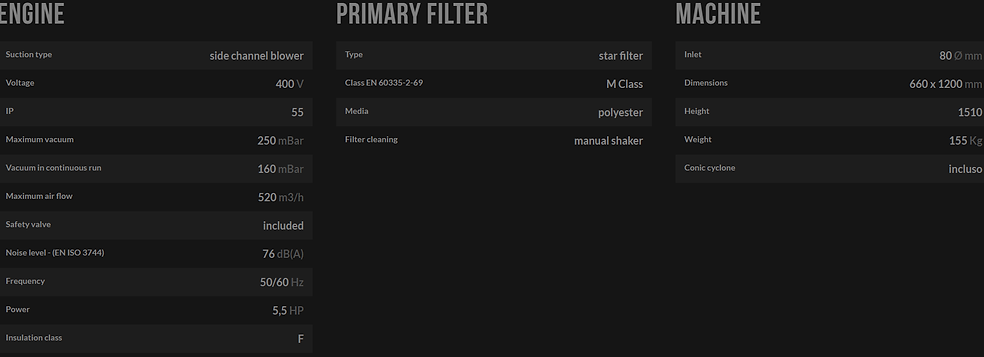

Technical Specification